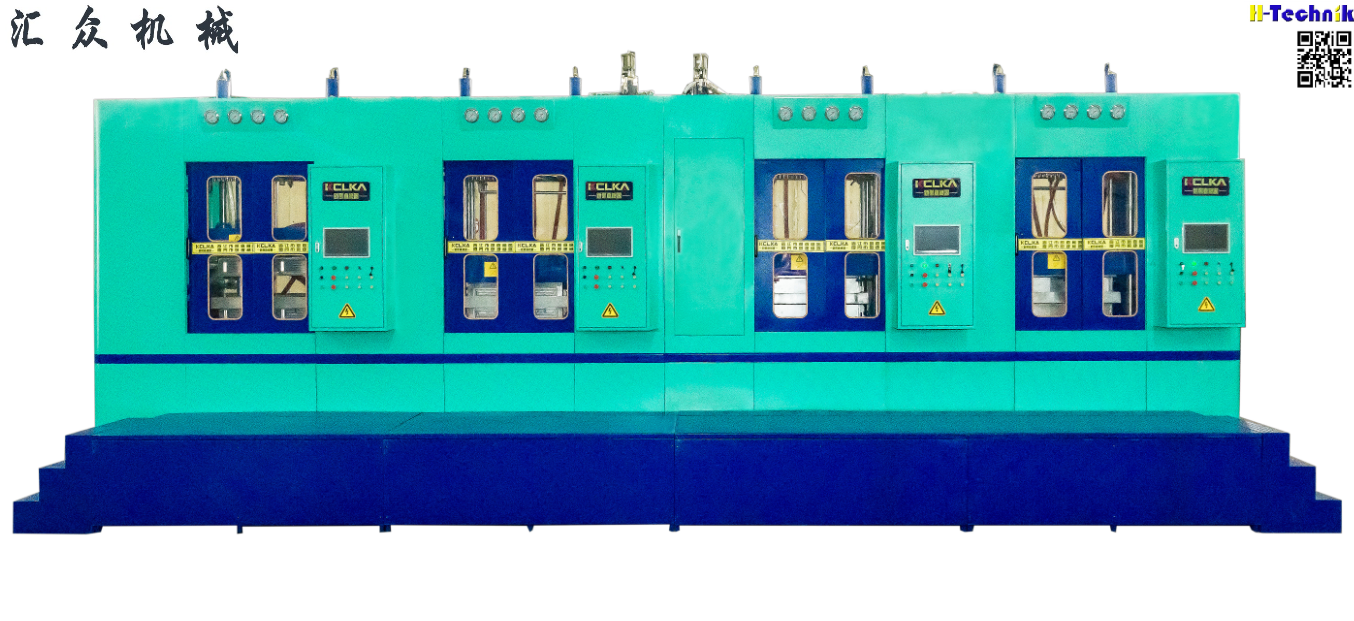

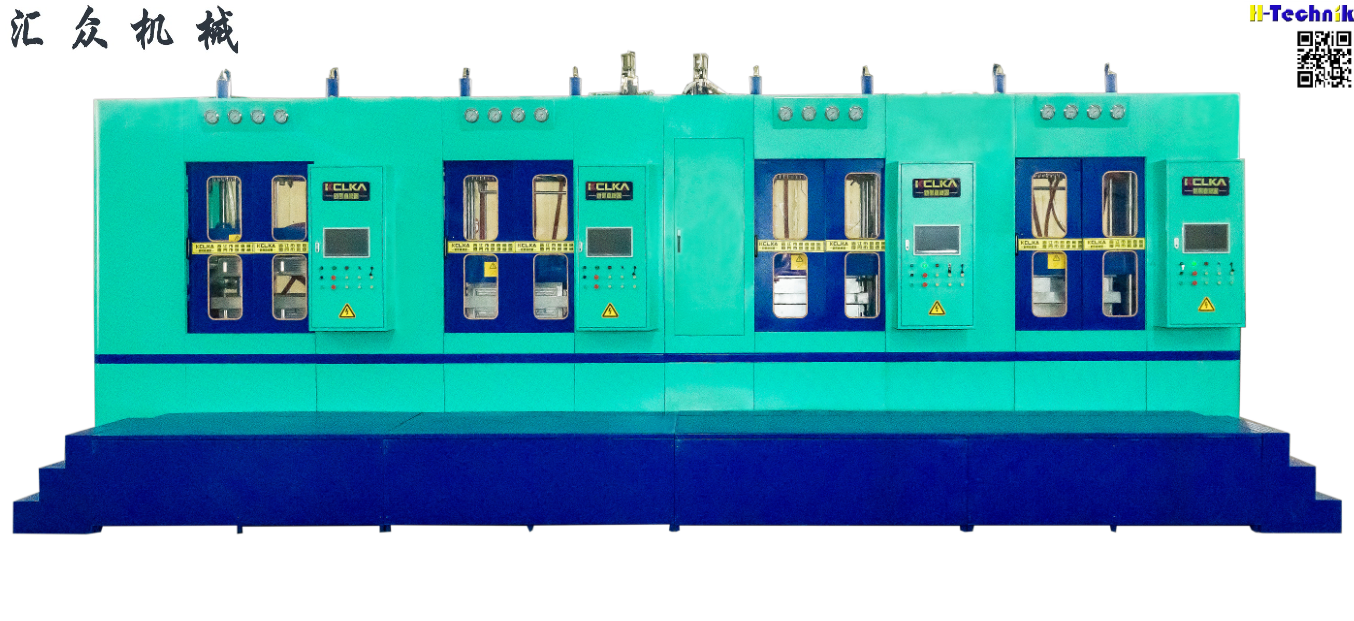

Semi-Automatic ETPU Foaming Machine PV 850

半自动立式ETPU成型设备 PV 850

Semi-Automatic ETPU Foaming Machine PV 850

最新优化特色工艺

Our distinctive advance features:

每台设备模面分别可安装2-3双鞋底模具,

A complete machine can produce 2-3 pairs of male and female middle sole.

计划生产非常灵活,每模可随意选择生产或作打样穴位数量。

Production planning can be more flexible that the number of single mold can be freely choose to make sampling or standard production.

模具安装尺寸可任意调整更换,适合市面上所有机型的模具尺寸

The installation of the mold can easily be adjusted and suitable for the common mold size of all models on the market.

According to the different sizes of mid-sole, new innovative technology of single cavity adjustment of crack is used to solve the problem of uniform mold crack in the market at present, and small size mid-sole overweight problem is easily solved.

专为模内压一体成型定制的特种设备,上下可插入碳纤维板及双密度组合生产新型产品。

Special equipment specially designed for integrated In-molding mold, capable of inserting carbon fiber boards and producing new products with dual density combinations.

优化加热气蒸冲模工艺,减少加热过程中的蒸汽损耗,大大节省加热时间,而且蒸汽可收集到蒸汽回收系统,降低生产成本。

Optimize the steam purging process, reduce the total steam loss during the heating process which can greatly save the steaming time, and steam can be collected into the condensate recovery system, reducing the total production costs.

可兼顾所有以饱和蒸汽成型鞋底的爆米花原材料

Can accommodate all types ETPU popcorn raw materials for saturated steam farmed mid-sole.